- ALGER SIFTER

- BALL BEARING MILL

- BIG BAG FILLING FACILITY

- BIG BAG UNLOADING STATION

- CALCITE COATING PLANT

- CALCITE MICRONISING PLANT

- CONSTRUCTION CHEMICALS PLANT

- DOSING, WIEGHING, MIXING AND LIQUID MIXING UNITS

- DRYING SYSTEMS

- FLAPS AND FEEDERS

- HAMMER CRUSHER

- JET PULSE FILTER

- MICRONISED GRANULE PLANT

- PACKAGING AND WRAPPING

- PERLITE EXPANSION PLANT

- PLASTER PRODUCTION FACILITY

- RAYMOND

- SEPARATOR

- SILO AND SILO UNLOADING SYSTEMS

- SILO TOP FILTER

- VERTICAL AND HORIZONTAL CONVEYING SYSTEMS

- VIBRATING MILL

- VIBRO SIEVE

- DESCRIPTION

- TECHNICAL FEATURES

- PRODUCT VIDEOS

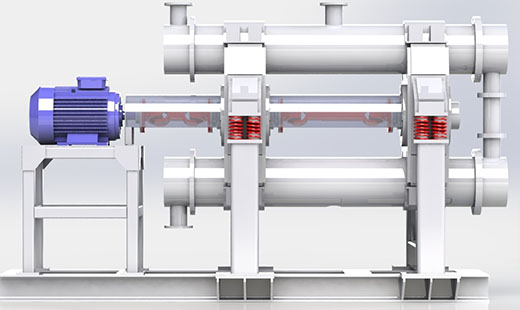

Vibrating mill is a new generation machine used to grind products with a low cost of energy consumption designed by EGEAY Machinery. Most important features of our crushing machines are their low cost of maintenance and their longevity.

Vibrating mills can be used in wide field of application area for process engineering tasks. Due to its easy handling, versatility and operational efficiency it is becoming important in different industries. It can be used dry and wet grinding processes.

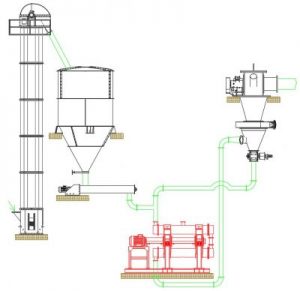

Depending on the type of product and process product input can be done at different points of the machine. The product entering the machine is grinded between the conical casting, shaft or ball (depending on the process) in the vibrating body and passed to a lower body. The product exiting the machine is absorbed by jet pulse filter and with the help of a separator is classified thus end product is achieved. Grinding material size adjustment is easily done according to your request while the vibrating mill is under vibration control. The machine is designed to grind very hard materials into very small powder particles. Machine capacity can vary according to the size and hardness of the material to be ground.

Vibrating mills are mounted on the chassis according to their dimensions.

- Vibration setting can be done easily

- Can be added to electricity control panel easily

- The Mills are designed for dry or wet grinding according to the process

Model | Diameter | Length | Feed size | Evacuation Size | Capacity | Motor kW | |

Dry | Wet | ||||||

(mm) | (mm) | (mm) | (mm) | (kg/h) | (kw) | (kw) | |

20EV | 200 | 300/600 | 0-15(max.30) | ≤0.01 | 0.1-150 | 1.9 | – |

22EV | 200 | 1250 | 0-15(max.30) | ≤0.01 | 20-500 | 5.5 | – |

35EV | 350 | 2310 | 0-15(max.30) | ≤0.01 | 50-3000 | 22 | – |

50EV | 500 | 3400 | 0-15(max.30) | ≤0.01 | 200-10000 | 75 | 90 |

65EV | 650 | 4525 | 0-15(max.30) | ≤0.01 | 400-20000 | 160 | 200 |

The feed size of the vibratory grinder ranges from 0 to 15 mm (max. 30 mm), while for regular and continuous processes the product size is less than 0.01 mm. In some special processes, it can be reduced to 0.003 mm.

- ALGER SIFTER

- BALL BEARING MILL

- BIG BAG FILLING FACILITY

- BIG BAG UNLOADING STATION

- CALCITE COATING PLANT

- CALCITE MICRONISING PLANT

- CONSTRUCTION CHEMICALS PLANT

- DOSING, WIEGHING, MIXING AND LIQUID MIXING UNITS

- DRYING SYSTEMS

- FLAPS AND FEEDERS

- HAMMER CRUSHER

- JET PULSE FILTER

- MICRONISED GRANULE PLANT

- PACKAGING AND WRAPPING

- PERLITE EXPANSION PLANT

- PLASTER PRODUCTION FACILITY

- RAYMOND

- SEPARATOR

- SILO AND SILO UNLOADING SYSTEMS

- SILO TOP FILTER

- VERTICAL AND HORIZONTAL CONVEYING SYSTEMS

- VIBRATING MILL

- VIBRO SIEVE